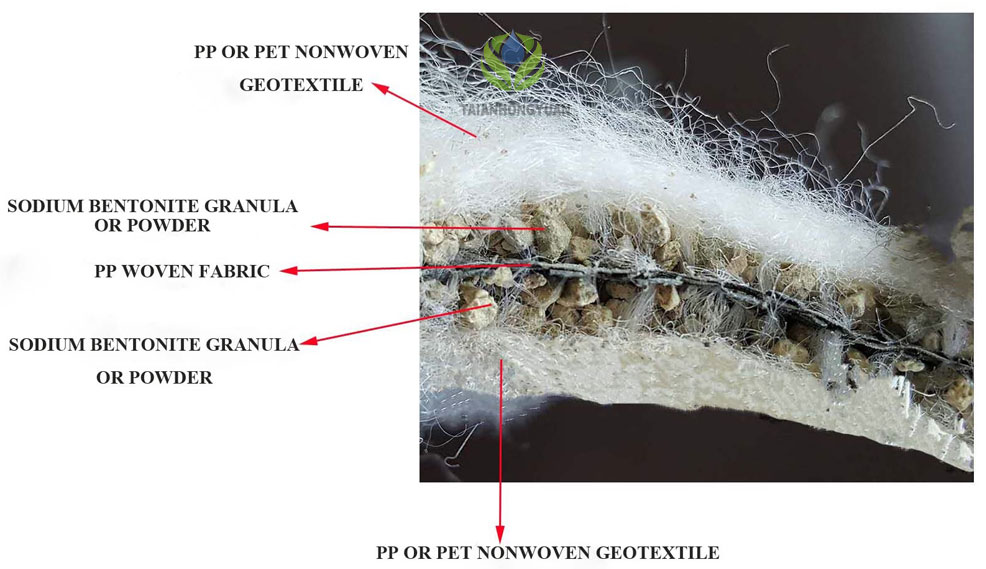

| ■ Geosynthetic clay liner - 5 layers introduction |

Because the quality of GCL is uneven in the market, also the soil layer of sites base and backfill are sand, which may affect the waterproofing, so we need to design double needle punched with two layers of sodium bentonite.

There are five layers from the top: nonwoven geotextile, sodium bentonite granular, PP woven fabric, sodium bentonite granular, and nonwoven geotextile. Both of the materials are needle punched together, and both sides of PP woven fabric are filled with bentonite granular. During the production process of 3 layers of GCL, when the upper surface of nonwoven geotextile is wrinkled, the quantity of bentonite granular will be reduced between woven and nonwoven geotextile. But for the double sides needle punched, when there is a winkled area, the lower layer will be filled with more bentonite granular, thus making up for the reduction of bentonite granular lose.

| ■ Advantages of the double sides needle punched GCL: |

1.The permeability coefficient is increased: the permeability coefficient is more than 5 times of the three basic GCL.

2.In view of construction, the GCL has the nature to strengthen the repairing, Especially for the underlayer of GCL, and the scratch and breakage caused by the drag and drop of the soil foundation. This kind of damage is difficult to be found when it is checked in the lower layer of the GCL. Even if the underfloor damage is great, the upper layer of the GCL can retain the effective waterproof structure of the nonwoven geotextile bentonite granular and woven geotextile.

3.Double sides needle punched GCL is stronger, there are two layers of nonwoven and one layer of woven fabric, which can not only provide a tightened reinforcement after the swelling bentonite granular, but also can prevent the puncture of the natural growth of roots in the backfill, and the CBR can be twice of common GCL.

4.The construction method is the same as the 3 layer of GCL which can not increasing the laying cost.

| Previous:Geosynthetic clay liner - 5 layers | next:Landscape project |

Tel

Tel

Products

Products

Contact

Contact

Home

Home